Wonders of our World #2: The "Big 3" of the Sea

We take a look at the South Korean shipyards that power world trade

On the southern coast of South Korea lies an industrial world wonder that most people will never think of, and yet shapes our modern world on a grand scale. Sprawling along shorelines near cities like Ulsan and Geoje sit monumental shipyard complexes, home to gargantuan cranes, dry docks, and production facilities on a scale nearly incomprehensible. This is the beating heart of Korea's immense shipbuilding industry - a powerhouse of engineering innovation and manufacturing might. For over 50 years, these shipyards have constructed an outsized proportion of the types of vessels that carry 90% of globally traded goods, playing an indispensable role in building the modern integrated global economy.

But just how outsized is South Korea’s contribution to global shipping? Despite being home to less than 1% of global population, in 2020, the South Korean shipbuilding industry accounted for 29.8% of global tonnage ordered, and in 2021, reached 37% of total orders (17.37 million of 46.96 million CGTs)

Three massive Chaebol companies - Hyundai Heavy Industries, Daewoo Shipbuilding & Marine Engineering, and Samsung Heavy Industries - operate the main South Korean shipyards and essentially dominate the world's shipbuilding market. Their origins trace back to the 1950s and 60s as South Korea embarked on their journey towards the industrialized country we know and love today. The country strategically nurtured the shipbuilding industry (among other notable standouts like electronics) and has been climbing the manufacturing value chain ever since. In the 90s, the Won crashed, and South Korean ships got even cheaper for international buyers. Because of this, South Korea would pass Japan in terms of cargo tonnage ordered by the early 2000s.

Today, the cluster of shipyards run by the Big 3 employs over 100,000 skilled workers. Workforce training programs ensure a pipeline of technical talent and craftsmanship passed down through generations. The shipyards operate as highly efficient manufacturing ecosystems designed to construct vessels rapidly. Automated cranes hoist and weld together immense pre-fabricated sections with precision.

The dry docks that the ships sit in pump out water to expose a ship below decks for outfitting. Gantry cranes running on rails tower overhead moving components weighing thousands of tons with ease. These shipyards make it look easy, but this is something that has taken hundreds of years to perfect, with the first crude oil carrier built by Hyundai: the Atlantic Baron, failing to match up at the central joining point (these ships are so big, they were built in two halves and joined later at midships).

Vast Impacts on Globalization and Trade

The global scale and impact of Korea's shipyards becomes clear in the numbers:

Korea's big three shipbuilders have capacity to construct over 3 million compensated gross tons (CGT) per year, representing 35-40% of total global shipbuilding capacity.

Hyundai alone built 57 million CGT from 2003-2013, including some of the world's largest container ships, oil tankers, and liquefied natural gas (LNG) carriers.

Ships built in Korea account for 35-45% of total global shipping gross tonnage across vessel types.

The ships constructed in these yards end up serving in practically every major shipping route and trade corridor. Korea's shipyards manage to be both tremendously diversified and highly specialized. They can construct cargo ships, passenger vessels, oil and chemical tankers, and even offshore structures. Yet they excel in building sophisticated high-cargo vessels optimized for quality and efficiency. Because cargo ships carry 90% of traded goods by volume, and Korean ships account for ~40% of that capacity, that means that ~36% of globally traded goods flow through these ships.

Pioneering Large and Efficient Ships

Korea's shipyards have demonstrated continued innovation in designing and building increasingly large ships for economies of scale. The country was an early pioneer in constructing supertankers, mega container vessels, and massive liquefied natural gas carriers, and today they dominate these spaces.

South Korean shipbuilders have built ~66% of the global LNG fleet, of which 22% was built by Japanese builders, 7% by Chinese builders , and the rest built by a combination of shipbuilders in France, Spain, and the United States. The Korean share is expected to jump again later this year, when a pending deal with Qatar for 40 LNG carrier vessels closes. This is a large share of the global fleet, which is only about 640 vessels in total, many of which are smaller than the planned Qatari vessels.

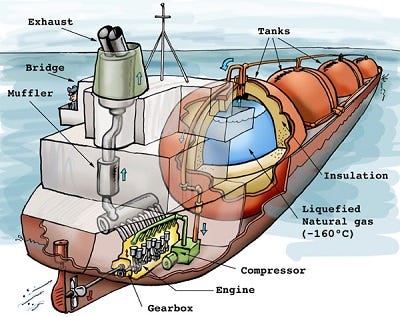

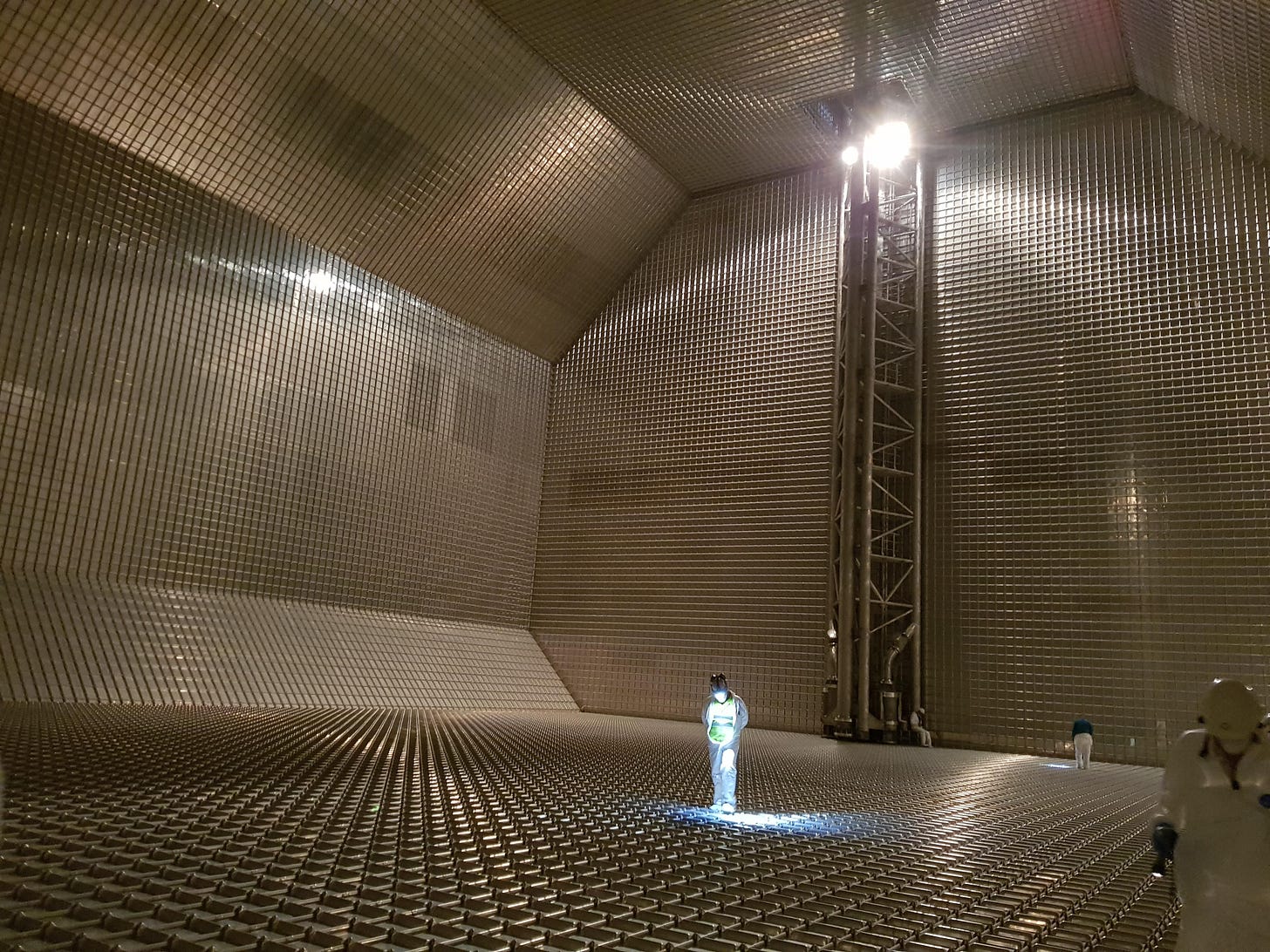

What makes LNG carriers uniquely important is their effect on the global energy market. Without these carriers, the transition from oil based fuels to natural gas would have been much slower. Each of these ships (Qatar max Class) carries a LNG load sufficient to power 70,000 American homes for a full year. This outsized energy payload is largely due to the LNG being about 6x denser than the gaseous form of natural gas, which stovetop consumers would be most familiar with. However, to reach these levels of densification, the gas needs to be kept extremely cold (-160 degrees C). In the spherical Moss Tank configuration above, this is achieved with lots of insulation, while the cryogenic membrane system below uses a mix of composite and stainless steel panels that are structurally supported by the ship’s hull. Of course, some of the gas warms up and expands in transit, but the crafty shipbuilders have thought of this, too! As some of the gas warms and changes state (a process called boil-off) it is used as fuel to power the ship’s engines. This way, the tanks experience the minimum pressure stresses and the ship can have extra room to carry LNG rather than conventional fuel.

LNG is important as a transitional fuel when it comes to reducing emissions and moving towards a greener grid. In combustion, LNG produces 45% fewer C02 emissions than coal , and 30% fewer emissions than oil. This won’t stop climate change, but with the arctic shipping lanes opening up, natural gas reserves from the far north of countries like Russia and Canada are becoming more and more accessible. Spillage of LNG is also less detrimental to sea-life, as it quickly evaporates upon warming, compared to oil which can sit at the surface and pollute oceans for months. Specialized LNG carriers with icebreaking sterns were built by the Daewoo Shipbuilding & Marine Engineering (DSME) shipyard in 2017, and access to these energy reserves may prove vital in the future.

LNG ships have also played a large role in recent geopolitics. After Russian gas exports via pipeline were cut off, U.S. shipments of LNG to Europe more than doubled, preventing a localized energy crisis on the continent and strengthening the will of European democracies.

Shipping is important. It allows people from around the world to trade and specialize to degrees never before thought possible. By expanding access to global markets, shipbuilders protect us from price shocks, shortages, and famine. In remarkable contrast to the dispersed and diverse world they create, the shipyards that are responsible for connecting the global economy are uniquely concentrated in East Asia, and especially so in just a few cities in South Korea.

So why do I think these shipyards deserve the #2 spot in our list of modern "world wonders"?

It's a remarkable feat of engineering. The shipyards themselves are marvels of industrial scale and marine engineering. The sheer scale of the trade network - spanning the globe, and its effects are also routinely undervalued. Earlier in the post we described how 90% of globally traded goods travel by cargo ship, and how 36% of that volume is Korean-made. Considering that global trade is worth ~$25T a year, it’s safe to say that these shipyards are a great example of high-impact infrastructure. They’re important to trade, energy, and democracy, and they largely remain unknown to the everyday person.

For these reasons, I believe the shipyards of South Korea (run by the “Big 3” Chaebols of Hyundai Heavy Industries, Daewoo Shipbuilding & Marine Engineering, and Samsung Heavy Industries) are collectively a modern world wonder.

-Connor, Of All Trades.

Links you should click