Wonders of our World #5: The TSMC

How the infrastructure of a single company is essential to modern life.

Semiconductors. Perhaps one of the most important technologies in our modern world, and integral to our experience of day-to-day life. They’re in your car, in your house, and in whatever device you’re using to read this post. Since the discovery of semiconductors 1874 and their subsequent use in the invention of the first transistor in 1947, the complexity of our computing hardware has reached dizzying levels. To illustrate this, here is a replica of the first transistor, which replaced the vacuum tube as the basis of computing. This transistor may seem small when compared to the hand in frame, but consider for a moment that the typical modern smartphone contains 2,000,000,000 (2 billion) transistors, each constructed on a microscopic scale. Whereas transistors started out at sizes as big as a fingernail, you now need access to an electron scanning microscope to even image the transistors within the most current chips.

But have you ever stopped to wonder where these intricately constructed chips come from? Surprisingly, they are almost exclusively from Taiwan, and almost exclusively from one entity within Taiwan, the Taiwan Semiconductor Manufacturing Company. This is especially true when considering the most recent generation of chips. the T.S.M.C. accounts for more than 50% of semiconductor manufacturing capacity as a whole, and in the range the most advanced chips <10nm, the T.S.M.C. makes up 92% of manufacturing. They operate 10 major factories on Taiwan called “fabs” that produce the overwhelming majority of these advanced chips, and the company is the 10th most valuable corporation in the world, worth as much as 540 billion USD.

This domination of the industry is maintained mainly through secrecy and discretion, and the TSMC only allows foreign based plants to produce 2nd rate chips (although this may change in the future with new competition on the scene from Samsung, who are building a 17 billion dollar factory outside of Austin, Texas. While foreign companies often design the chips, the TSMC represents a monolithic concentration of knowledge when it comes to the extremely difficult process of manufacturing them at scale. This exclusivity of knowledge and the keystone position that the T.S.M.C. fabrication sites hold in the global economy makes the T.S.M.C. fabs some of the most important buildings on earth.

So what makes these fabs so difficult to replicate? Let’s take a deeper look at one of these modern marvels. Material on their fabs and how they work is understandably hard to come by, due to the important role that the chip fabs play in the geopolitical strategy of Taiwan and the market power of a 500 billion dollar company. Fab 18, their new 5nm manufacturing plant, is 3 times the size of the AT&T stadium in Dallas Texas with a total floorspace of 950,000 square meters, and cost more to build than the world’s most advanced aircraft carrier USS Gerald R. Ford, at just under 20 billion dollars.

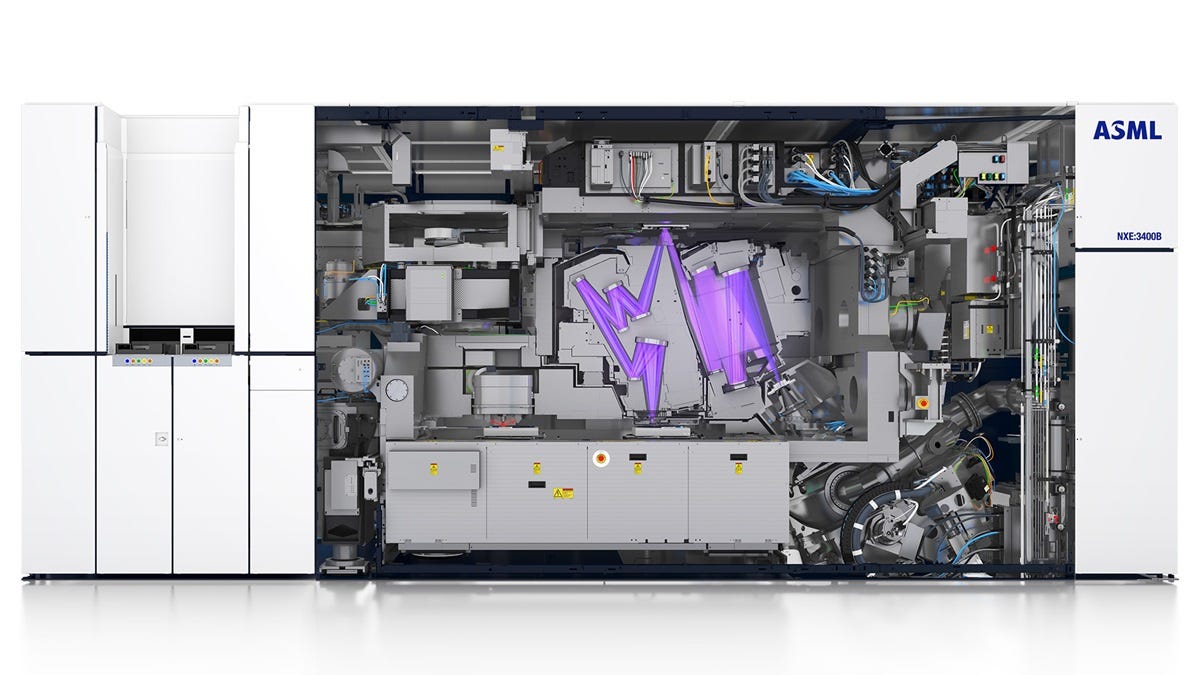

The TSMC fabs are among the most finely controlled human built spaces in the world. As the size of each individual transistor decreases, the room for error and entropy also decreases. Photolithography costs have ballooned as the industry has begun to push up against the limits of what is physically possible. EUV, standing for “extreme ultraviolet” is one of the newer frontiers in photolithography.

Next gen EUV machines can cost up to 300 million USD per unit, and their size and complexity means that the volume of cleanroom also must increase to facilitate them. Fab 18 has a 160,000 square meter cleanroom, which is maintained at a cleanliness level less than 1 stray particle greater than 52nm (virus scale) each week, in order to facilitate the use of EUV.

If something were to happen to the handful of TSMC fabs, whether as a result of a natural disaster, a war with China, or a terrorist group waging war against the emergence of hostile A.I., it’s likely that research and development would slow to a halt, and that market sectors large changes would have to be made in how we live our lives. For this reason, and the exposure of the fragility of the supply chain that the world witnessed in the past 2 years, other nations and markets have begun to awaken to the potential of a chip shortage should something happen to the complex of fabs in Taiwan.

This has spurred some competition, most notably from Samsung Foundry, who are in the early stages of construction of a 17 billion dollar fabrication foundry just outside of Austin, Texas. However, this foundry and other competitor foundries like it will likely not produce chips smaller than the 10 nanometer range for the foreseeable future, leaving the TSMC with a commanding lead at the cutting edge of the industry.

Having looked at its role as a keystone in the electronics supply chain, and its bright future as an incubator for innovation, I think it’s clear that the TSMC improves the lives of billions of people around the world and will continue to do so throughout the 21st century. As hostage infrastructure that is important to both superpowers, it helps cool tensions in the geopolitical arena and plays a large part in keeping the people of Taiwan free. The sheer precision of the manufacturing that goes on within the walls of the TSMC is a marvel in and of itself, and for these reasons, the TSMC fabs earn 5th place in my world wonders list. Stay tuned as we count up the list in upcoming posts, and comment below what world wonders you think should make the list!

-Connor, OfAllTrades.

Like this article? Please Subscribe!

Know someone who would? Please Share!

And if any of you readers out there are secretly crypto millionaires and would like to leave a tip, please check out https://alltrades.eth.xyz/

Further Info For the Curious:

This was a really interesting article to write and it inspired me to learn way more about semiconductors than I ever thought I would going into it. If you do one thing today, please check out Asianometry on Youtube, (link here) and on Substack (link here). The author Jon Y is truly a domain expert and produces some of the best writing on the subject I could find.

Do you think that the concentration of this capacity in a single place is dangerous in a relevant way? I can think of some conception of this where resilience of semiconductor supply is mostly a positive externality so no one really invests in it. Should governments be investing in diversifying supply?